So you're probably not thinking about RF testing right now.

Totally normal. In the modern world, hardly anyone thinks about RF testing. Why? Because we take it for granted that all of our electronics and devices communicate perfectly over invisible electromagnetic waves. And when these emissions deviate unexpectedly, it becomes very interesting (and by interesting, I mean costly, messy, and sometimes lawyer-involving).

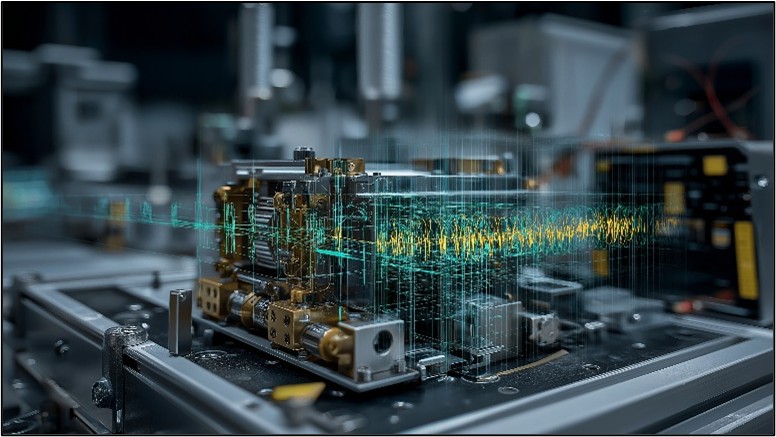

Welcome to the world of invisible electromagnetic waves, where either everything is going great or nothing is. With nothing in between, not to mention you can't see them, it's all a little strange.

The Invisible Infrastructure We All Depend On

While you are reading this, you are already experiencing several RF systems transmitting all around you. Your phone, your WiFi, and possibly a smart speaker, fitness tracker or some Bluetooth device that seemed like a great idea when you bought it.

Every one of these systems has to pass through rigorous testing called RF testing. This is done to check whether such a system is doing what it was set out to do. Also, whether it is not interfering with your neighbor's system or radio, more importantly, medical equipment, or aviation communications.

The testing isn't optional. The IMT-2020 5G standard is what lets wireless technologies play together within the same electromagnetic spectrum. That is actually a pretty remarkable thing.

What keeps RF engineers consistently enthusiastic and upbeat (apart from good coffee and a genuine interest in electromagnetic theory)?

The ways tests are done are changing quickly, just like the systems they are used on.

When Precision Actually Matters

Let me take you through a scenario—and it's one that happens for real in aerospace companies.

An RF system tests beautifully in the lab. In other words, the numbers are doing priceless things. They are beautiful numbers that engineer people love because they suggest that the design is working. Moreover, the design is actually working much better than the predictions. It passes every qualification test with comfortable margins.

Then it gets installed in the actual platform.

And it works... fine? Mostly? There's a little behavior that happens sometimes in certain cases but under proper conditions that wouldn't matter in most applications but matters a lot in mission-critical applications.

After months of investigating, it turns out to be something nuanced, maybe a thermal expansion characteristic in a connector that only shows up under certain vibration profiles and set of temperatures, which happen under operation.

The initial lab testing had completely missed it.

The testing was not deemed inappropriate; in fact, by traditional standards it was excellent. But no matter how comprehensive lab testing may be, it has tested components in isolation in complex environments never faced in actual deployment.

That's why modern RF testing methodologies are moving toward something really new.

Testing Environment and Possible Solutions

Reviewers have noticed something: test under a realistic environment.

The RF testing community shares this ethos and is building new generations of increasingly sophisticated testing methodologies.

Here's what's emerging:

We provide integrated environmental testing where you are not just testing the RF performance in isolation, but rather testing it while stressing the system with temperature cycling, vibration, humidity, altitude simulation – in short recreating the real conditions the system will encounter.

Complex defense and aerospace systems must be tested in an anechoic chamber over-the-air that can replicate real-world multipath propagation, interference scenarios, and operational conditions. After all, if you're building a defense/aerospace system you want assurance the system works reliably in all circumstances.

Test sequences that allow tests of long duration to run continuously, thus freeing engineers from running the same procedure again and again. They can now spend their time analyzing interesting results and solving complex problems.

Digital twin integration is when your physical test lets the simulation model know continuously. If the results diverge, that divergence gives you valuable data that enhances your predictive ability

The Anechoic Chamber: Engineering Silence

Quick question—have you ever been inside an anechoic chamber?

They're remarkable. The surfaces are made of foam pyramids that absorb electromagnetic radiation, but also sound, which is a happy side effect. When you are inside one with the door closed it is so silent one starts to hear things you don't normally notice. You realize that there are other sounds which you are not usually mindful of.

But for RF testing? They're essential. They provide a space where the only RF signals present are the ones you bring in intentionally, thereby allowing you to measure what your system is doing without interference from the many RF signals present in any populated area.

Today's anechoic chambers are ubiquitous, large, and sophisticated: multi-axis positioning systems permitting devices to be rotated into any orientation while continuous measurements are made; probe systems allowing quick location measurements of the three-dimensional radiation pattern to a very high level of accuracy; chambers being large enough to enable sizeable assemblies, even complete systems, to be tested.

Some facilities spend heavily on these capabilities because the payback in reliable system performance is considerable.

When Testing Reveals Hidden Patterns

Here's a story that illustrates why this matters.

A radar system was having irregular faults during field trials. Not constantly. Just... sometimes. Under conditions that seemed random initially.

Everything was within specifications as per the standard RF testing. The system met all its requirements. However, in operational scenarios these subtle issues kept coming up.

The breakthrough came when engineers began to correlate the anomalies with environmental indicators—temperature, humidity, time of day, geographic location. Actually there was a pattern, it just was not immediately visible.

They implemented testing that involved both environmental factors and long-duration operational profiles which revealed the root cause: a subtle interplay between the RF subsystem and temperature differences that occurred under specific circumstances.

Once identified, the solution was straightforward. They had to test approaches beyond traditional methodologies to find it.

The Evolution Toward Predictive Testing

What's really exciting is where this is heading.

These days, modern RF testing is becoming more and more predictive. For example, using machine learning algorithms to detect failure modes before anything goes wrong in the field. Additionally, engineers are correlating vast amounts of test data to find patterns human analysts may miss. Also, they are constantly updating the model based on how systems actually behave when deployed in the field.

The question is changing from "did this pass the test?" to "how will this perform across its entire operational envelope over its entire service life?"

The emerging capabilities include:

Making the Invisible Visible

What is fascinating about RF testing is that it makes invisible occurrences measurable, predictable and reliable. You can't see radio waves, but you can absolutely characterize their behavior, how they interact with materials, how they propagate through environments, and how they function under difficult circumstances.

The testing methodologies must develop alongside the advancements in our systems, which are higher frequency operation, sophisticated modulation schemes, denser integration, demanding new applications, etc.

That indicates that there are plenty of genuinely interesting engineering challenges as well as continuous innovation.

The motive for excellence in RF testing is precisely what motivates organizations like Mentis Sciences to work in advanced technology fields. They have a serious commitment to validation techniques that ensure that complex systems work reliably when it counts. Learn more about their approach to engineering excellence at www.mentissciences.com— because in mission-critical applications, testing isn't just verification, it's the foundation of confidence.