Over 25 years at the forefront of materials innovation, we at Mentis Sciences have seen incredible strides in the evolution of composite engineering. Advanced composites have been instrumental in transforming industries – with their versatility and strength-to-weight ratios playing a crucial role in their success.

But modern composite performance was not born overnight. In fact, today’s composites were developed through decades of pioneering research and development. Composite testing plays a key role in unlocking the potential of these remarkable materials. As we celebrate the success of today’s advanced composites, read on as we reflect on the fascinating history around composites and how researchers have evaluated them to craft new innovation.

The Dawn of Composites

In the contexts we discuss today, composites might sound like cutting edge technology. However, their origins actually reach back thousands of years – even to ancient Mesopotamia! The earliest composite materials may have been crafted around 3400 B.C. as laminated wood strips were utilized to create plywood.

Later, the Egyptians created artifacts such as death masks out of cartonnage made from linen or papyrus soaked in plaster. There’s also evidence that construction projects made use of early composite technology, as mud bricks were often reinforced with straw.

Many other civilizations continued to look for stronger and lighter materials to utilize over the centuries. By the time we arrived in the industrial era and into the early 1900s, we were beginning to see advanced polymers like Bakelite that were reinforced with a wide range of materials including cotton and asbestos. This huge advancement was just the tip of the iceberg compared to what was to come, however!

World War II Propels Composites Forward

During the World War II era, these advanced composites came into the spotlight and transformed from something utilized for niche applications into a truly mainstream engineering material. Innovation grew in fiber-reinforced polymers (FRP), which fulfilled a need for materials that were both tough and lightweight. Soon, fiberglass composites were being utilized for radar installations and more – like reinforcing boat hulls.

At this time, developing further testing methods was essential for supporting the war effort and manufacturing. This represented tensile, compression, shear, and flexural testing – as well as the foundations of test standards and mechanical insight.

The Jet Age and Advanced Composites

The 1950s highlighted the usage of advanced composites during the jet age. In the field of aviation, extreme thermal and structural performance needs drove this next wave. Also, mission-critical aerospace applications called for even more rigorous testing protocols for these innovative materials. Compression after impact (CAI), fatigue, and high-rate testing provided vital data on damage tolerance and dynamic behavior. Materials were still evaluated with ongoing tensile, compression, shear, and flexure evaluations. Even when facing the harshest operating conditions, the creation of even more specialized tests gave engineers more confidence and insight the performance and failure modes of these advanced composites.

Expanding Horizons for Composites

Carbon fiber reinforced polymers and other advanced composites have expanded their usage into many, many industries – automotive, sporting goods, energy, and construction represent just a few. Because of their usage in so many sectors, test methods needed to meet different performance requirements. Testing, therefore, adapted to address lots of different challenges – such as for resistance of wind turbines or damage tolerance for cars after crashes.

With specialized testing becoming more affordable, many industries were empowered to adopt composites on a more widespread level. At the same time, standardization bodies like ASTM International, ISO, and SACMA collaborated globally to codify best practices for composite material testing. With more ways to assure the success of implementing advanced composites, composite engineering was able to further thrive around the world.

Modern Composite Testing

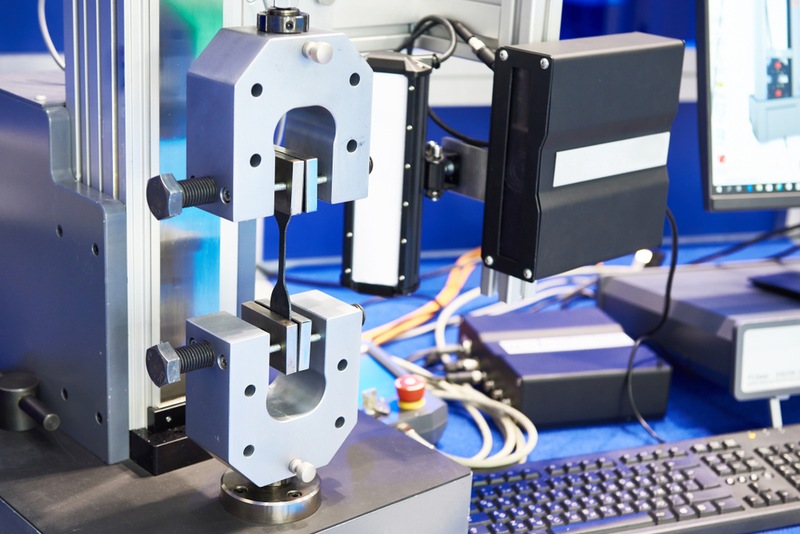

So, what does composite testing look like today? In 2024, plenty of cutting-edge equipment exists to leverage powerful data analytics capabilities and give researchers even more precise information about composites. Mentis Sciences aims to stay at the forefront and offer exceptional testing capabilities. Our composites testing systems can evaluate the full gamut of material behavior – addressing mechanical, RF, chemical, and thermal analysis. By continuously investing in developing new composite test methods and technologies, Mentis Sciences empowers our customers and partners to push the boundaries of innovation. As advanced composites revolutionize transportation, renewable energy, aerospace, and more, know that the success of these projects can stem directly from rigorous testing and engineering programs.

Conclusion

History shows that humankind is ceaselessly drawn to innovation and the development of new and improved tools to solve the problems that face each generation. Often, this means stronger, lighter materials – like those provided through composite engineering. What started as the development of basic wood laminates and reinforced bricks has evolved into today’s carbon fiber marvels, driving the creation of things like super-efficient aircraft and planet-scale wind farms.

Throughout this entire timeline, testing and a desire for knowledge about just how these composites behave has helped engineers to unlock and utilize their full potential. By standardizing these tests, better data can be drawn to make the seemingly-impossible possible with composites. Mentis Sciences will continue to invest in the future of composite testing and in its ability to reshape industries. We’re ready to push composite frontiers even further in the years ahead!