Few devices ever face conditions as extreme as those experienced by a missile radome: a passive, protective aeroshell designed to enable radar function and target acquisition. From the high-temperature demands of missile flight, to severe, stormy elements experienced in weather, radomes see it all.

Read on to learn more about this unique field of manufacturing, and how our team at Mentis Sciences works to help propel it forward.

Double duty

Like its name might suggest, a radome is tasked with the double duty of providing a protective dome while not interfering with the radar capabilities of the sensors underneath. This device must be strong and sturdy enough to provide physical protection from the elements, while allowing the transmission of radio waves conveying essential information about the radar equipment’s surroundings.

What is the role of radome manufacturing?

Because of its essential function, radome manufacturing has a wide variety of applications, including…

- Meteorology

- Defense industries

- Aircraft

- Maritime satellites

Bolstering the defense industry

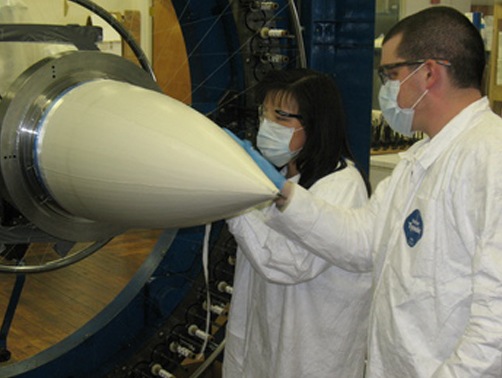

At Mentis Sciences specifically, our work in radome manufacturing revolves around equipping domestic and international missile systems. Our fabrication work utilizes braiding and hand-layup techniques, supported by two CNC cutting tables (with MultiSurf(r) software), CNC braiders, and Virtek LaserEdge(r) alignment systems used for precise, repeatable manufacturing and performance in extreme conditions.

Taking radome technology to new heights (and temps)

Speaking of extreme…

Our radomes are built to withstand them all, maintaining structural and electrical integrity under the intense demands of missile environments—specifically, they can hold their own at temperatures exceeding 2,000 degrees Fahrenheit. We take this extreme capability seriously: As one of the world’s leading radome manufacturers, we work to ensure that our radomes are up to the task of tomorrow’s challenges.

Testing and analysis ensures precision when it matters most

At Mentis Sciences, our efforts in radome manufacturing don’t stop at fabrication alone. To ensure the best possible materials and performance, we have assembled extensive material preparation and inspection equipment, as well as testing capabilities and analysis software. We are dedicated to the quantifying the performance of engineered solutions so that our clients can count on precise, dependable performance in a wide variety of applications.

Be sure to stay tuned to Mentis Sciences as we continue sharing insights into the fascinating world of radome manufacturing, engineering and more. As always, feel free to contact us for a closer look at our portfolio of work, and to see what we can do for your organization next.