We live at the intersection of materials science and engineering. Mentis Sciences pioneers advanced composites that push limits in extreme environments. Our customized solutions leverage the latest research to turn atomic-level innovation into real-world resilience. In this article, we’ll explore why our composites thrive where others falter.

What Sets Our Composites Apart?

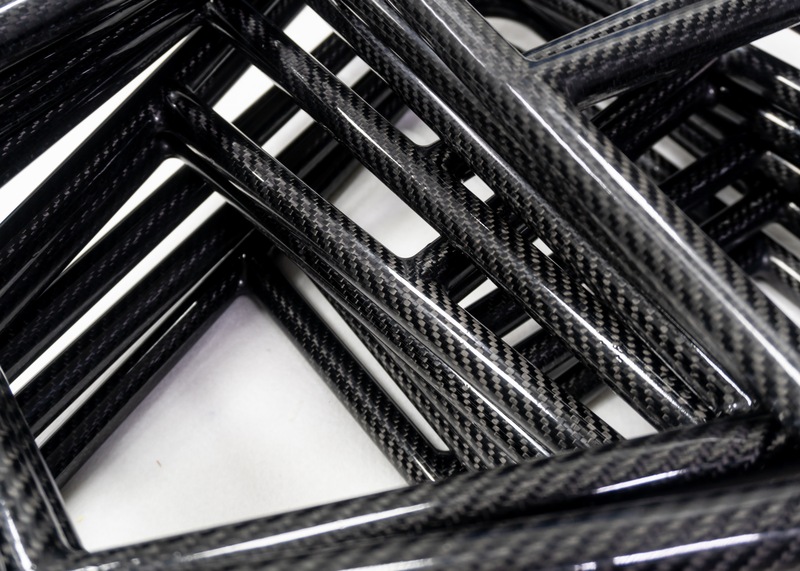

Mentis builds high-temperature composites tailored for each application. We combine polymer or ceramic matrices with a wide range of cutting edge reinforcements fibers like silicon carbide, carbon, quartz, aramids and alumina. The resulting materials merge the best aspects of each component. It's this fusion by design that enables exceptional performance when temperatures surge drastically.

Our composites owe their capabilities to deliberate engineering across dimensions, from microscopic interfaces up to component geometry. We can tune the ingredients - the resin systems, fibers employed, orientation choices and tailor the processing conditions for the environment at hand. This allows us to meet the performance need without adding excess cost into the materials solution. In a field often ruled by limitations, this versatility unlocks new horizons.

Conquering Extreme Oxidation

Materials exposed to high heat often face ceaseless assault as oxidation degrades them. Most metals react continually with oxygen under such conditions, corroding despite protective barriers. Ceramics, however, develop durable silica layers that resist oxidation remarkably. Blending these resistant ceramics into composites imparts heightened environmental stability.

The embedded fibers also dramatically sway resistance to surface ravaging. Carbon fibers, for example, gasify even with traces of oxygen present at extreme temperatures. Mentis often has developed robust OX/OX materials for the highest heat applications. The ability to balance factors like strength, stiffness, density and chemical durability empowers optimal designs.

Mastering Thermal Shock

Swift temperature spikes strain many materials past endurance, creating cracks or delamination as thermal shocks reverberate destructively. The speed that energy migrates through a system determines resilience when rapid heating or cooling strikes. Materials that transmit temperature changes across their width withstand the volcano-like spikes.

Mentis has demonstrated that our materials are highly tolerant of thermal shock. Testing has shown that they can handle a thermal temperature shock of over 1000°C in 15 seconds, and thermal soaks at 1000°C for 60 minutes with not damage . So Mentis’ composites maintain integrity even amidst extreme thermal cycling.

Compound Strength with Grace

Ceramics boast immense compressive strength yet suffer from brittle tendencies. Without reinforcement, surface defects trigger crack chains that avalanche towards full-scale failure. Even tiny flaws make ceramics vulnerable to rupture compared to metals that locally yield before fracturing. At Mentis, we intertwine the ceramic matrix with unbroken fibers spanning the entire composite. This allows extensive stress redistribution rather than concentrated overload at crack tips.

The fibers pull out and stretch instead of snapping in response to ceramic matrix microcracking. Crack arresting and large-scale bridging then plasticize material response. Our composites tolerate much more abuse before ultimate failure compared to their ceramic counterparts alone. With balanced fiber-matrix bonding tailored for the environment, components achieve reliable toughness where ceramics themselves would shatter instantly. It’s this intentional blend of strength and grace that permits radical lightweight designs.

Harnessing Exceptional Lightness

Mass compounds complexity across system lifecycles - from manufacturing equipment needs to transportation logistics to in-service energy budgets. Streamlining weight while upholding extreme thermal duty frees future thinking. Mentis empowers engineers to mix and match constituents for the challenge at hand, fusing low density and high durability. In aircraft, vehicles, and processes that expend large energy flows, replacing heavy conventional materials with tailored composites unlocks massive efficiency gains through mass reduction alone. It’s this basic physics that animates excitement around adopting composites for thermal management.

Unlocking Geometric Freedom

Casting high temperature resins and strategic fiber orientations within purpose-built molds permits Mentis to produce geometries once considered impossible. Curing under heat and pressure makes the matrix conform and grip embedded reinforcements. So rather than boxy builds dictated by joining approaches, components echo organic flow matched to stress contours.

Consolidating subcomponents and connections into integrated structures sidesteps incremental limitations while concentrating strength exactly where needed. With composites, complex architectures with conformal passages, undercuts and curved progression in section become buildable. This liberates the design innovation cycle from constraints rooted in outmoded conventions and standards.

The Future Beckons Boldly

High temperature composites distill relentless, deliberate science into practicable solutions. They overcome limitations that have stalled progress across industries and allow the realization of once merely imagined technologies. As researchers reveal new possibilities, Mentis applies this knowledge to customized composites that reliably withstand blistering conditions.

Ongoing advances continuously compound fundamental benefits for systems that operate where few tread. Lighter, stronger and more durable materials transform what is achievable, energizing fields like hypersonic flight. We remain committed to pushing composites progress - turning atomic-level discovery into real-world resilience that propels society forward.